Shifts in global trade and workforce demographics, coupled with the widening scope and capabilities of AI, are heightening manufacturing expectations within supply chain organizations. For chief supply chain officers (CSCOs), efforts to improve customer value and drive growth won’t succeed if they rely on a static manufacturing strategy.

Enterprise investments in automation, industrial Internet of Things (IIoT) and AI aim to solve this issue, but two-thirds of manufacturers aren’t aggressively redesigning their manufacturing strategies.1

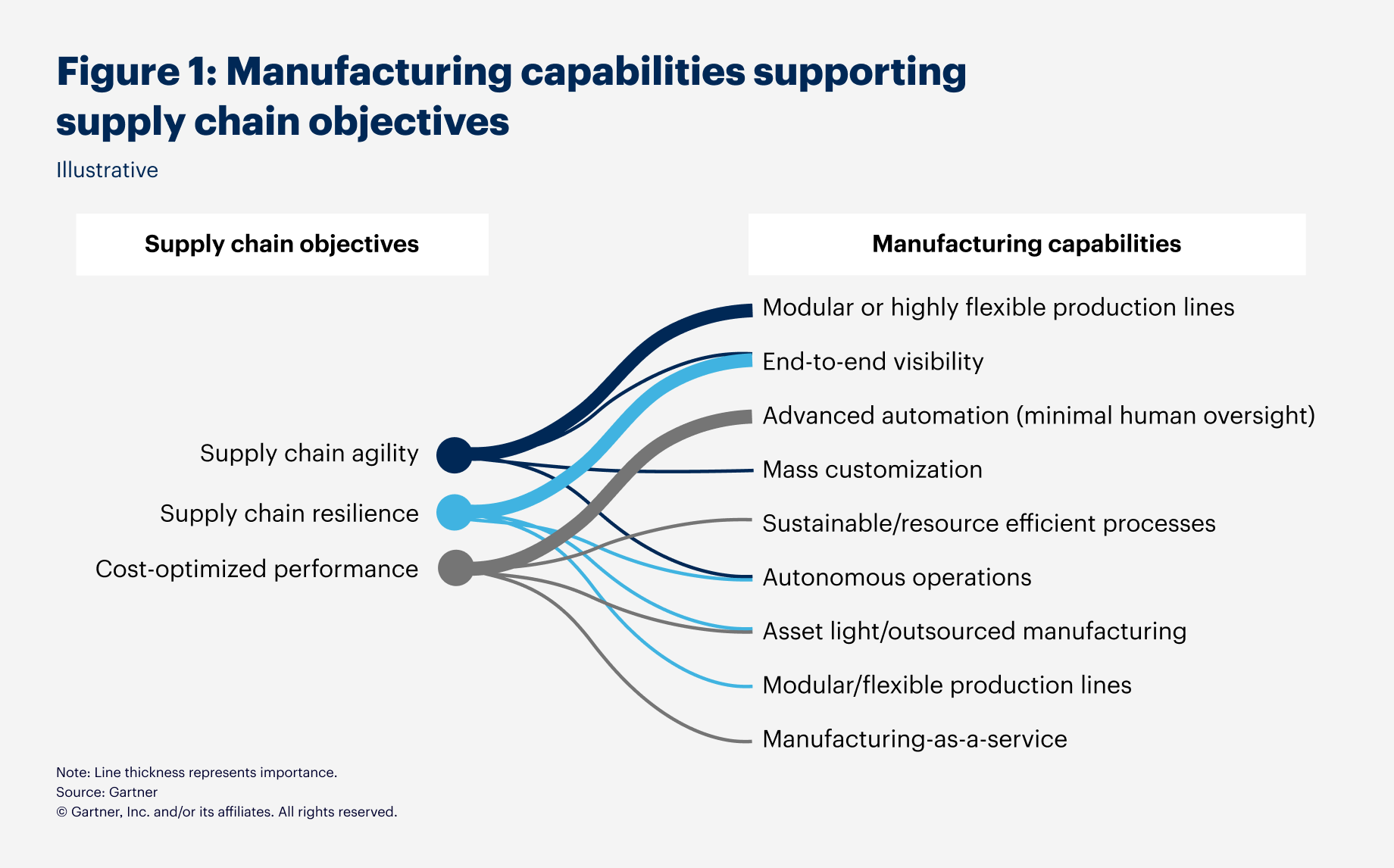

CSCOs have a unique opportunity to play a pivotal role in evolving the manufacturing operating model and ensuring it keeps pace with both enterprise and supply chain strategy. It starts with mapping manufacturing capabilities to supply chain objectives (see Figure 1). By aligning manufacturing strategies with key business outcomes, you can start to transform the manufacturing operating model into a platform for future competitiveness.