12 ways to secure supply chain networks against disruption while keeping costs in check.

- Gartner client? Log in for personalized search results.

Only 21% of chief supply chain officers (CSCOs) have a highly resilient supply chain network.

A resilient supply chain network has good visibility and the agility needed to rapidly shift sourcing, manufacturing and distribution activities.

This makes building greater resilience into supply chain networks a top priority.

But in most cases, increased resilience comes with additional costs, requiring CSCOs to balance efficiency and resiliency.

Download the report to explore 12 ways CSCOs can secure their supply chain networks. Discover:

- 6 factors to determine the level of resilience needed in manufacturing networks

- 6 ways that supply chain leaders can increase resilience in their supply chain networks

About Supply Chain Networks

In today's dynamic global environment, supply chains are confronted with a myriad of uncertainties—ranging from geopolitical tensions and financial volatility to fluctuating demand and supply conditions, as well as evolving regulatory landscapes. Experts predict that these uncertainties will persist, necessitating a strategic approach to supply chain network design.

Traditionally, the architecture of supply chain networks was crafted based on a singular set of forecast inputs, encompassing cost analysis, supply availability, demand projections, and service requirements. However, in an era marked by unpredictability, relying on a fixed set of inputs can lead to inaccuracies. This rigidity may result in a fragile network, ill-equipped to respond to shifting conditions, thereby requiring costly and frequent adjustments.

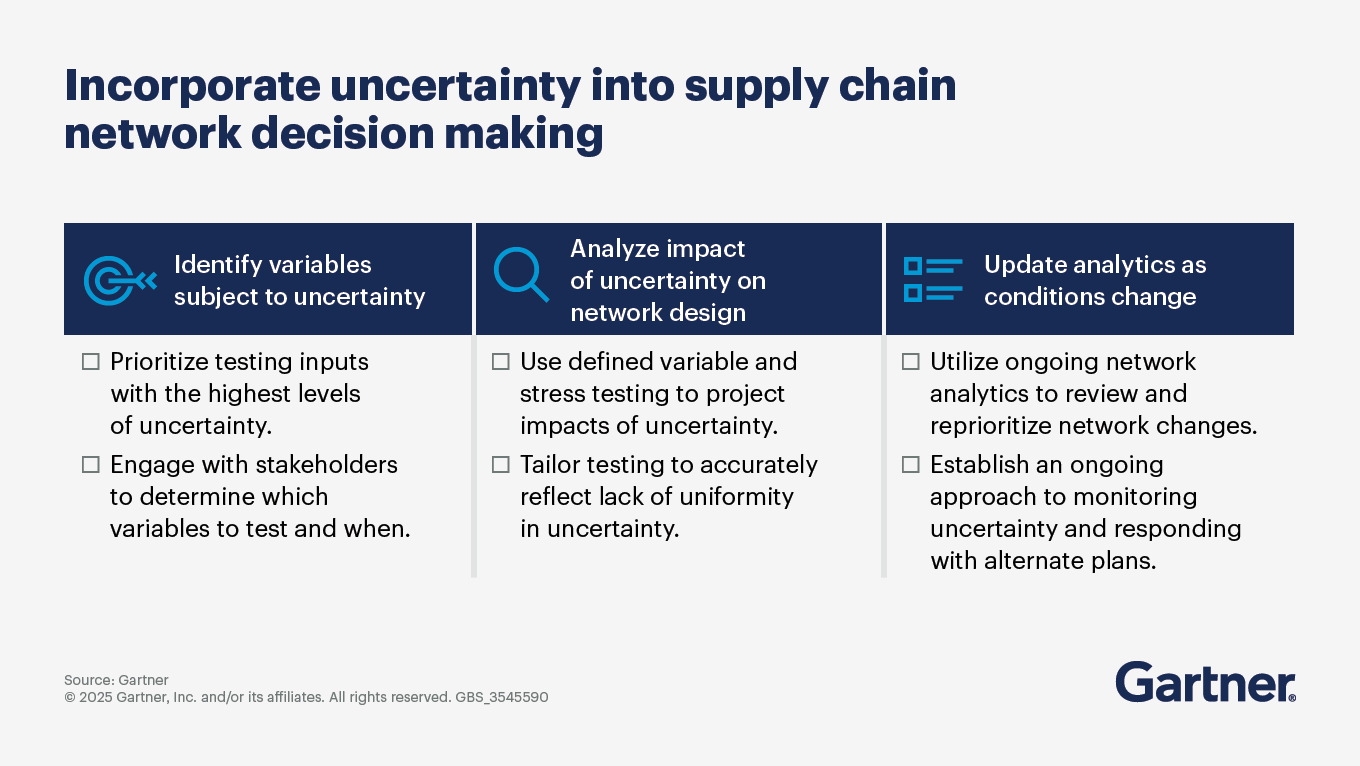

Gartner guides CSCOs and their teams to navigate this complexity by integrating uncertainty into their supply chain network design through a comprehensive three-step approach:

Identify influential inputs: Pinpoint the key factors driving recommended modifications to the supply chain network, ensuring alignment with strategic objectives.

Evaluate impact of uncertainty: Conduct thorough analyses to assess how input variability affects proposed network designs, enabling informed decision-making.

Embed flexibility into network analysis: Establish a proactive, robust, and adaptable framework for continuous network evaluation, fostering resilience and agility in the face of change.

By embracing this strategic approach, supply chain leaders can cultivate supply chain networks that are not only resilient but also capable of thriving amidst uncertainty, thereby safeguarding operational efficiency and competitive advantage.

Supply Chain Network FAQs

What is supply chain network design?

Supply chain network design is the optimization of the location and function of supply, manufacturing and distribution networks in support of an overarching company strategy and customer requirements.

What are supply chain network design tools?

Supply chain network design tools support the creation of network models with the application of advanced analytics to determine the optimal supply chain design in a structured, scalable and repeatable way.

How can you ensure your supply chain network design is successful?

Align network design initiatives with corporate and business objectives.

Align use cases and scope based on resource availability, capability and capacity.

Leverage sensitivity analysis and iterative modeling, and create a robust governance process to gain buy-in from stakeholders.