Invest now in key capabilities to empower the supply chain organization through 2030.

- Gartner client? Log in for personalized search results.

Preparing for the Future Supply Chain

Prioritize strategic investment to chart your path to future supply chain success

Chief supply chain officers (CSCOs) must tackle major hurdles to deliver value: AI leaps, stricter ESG rules, geopolitical shifts, data control and talent shortages.

But only 19% of CSCOs fully incorporate scenario planning into supply chain strategy.

Download Gartner’s eBook to determine which of 4 proven investment strategies is right for your organization to build a future-ready supply chain. Learn:

The 5 top supply chain characteristics to manage future scenarios

How to advance key operational metrics

Decision criteria and priorities to guide your supply chain transformation

Build a strong foundation for future supply chain success

Supply chain leaders are seen as critical enablers of business strategy. Even amid volatility, they accelerate investment in future capabilities. Learn by example to chart your path to success.

Supply Chain Vision

Real-Time Execution

CX for Supply Chain

Human-Centric Work

Sustainable Supply Chain

Tackle the priorities that will turn future supply chain vision to reality

To deliver business value amid ongoing volatility, global CSCOs face three major challenges:

CEO pressure. When CSCOs focus on cost control, their CEOs tend to believe that the supply chain isn’t doing enough to support business growth. This diminishes the perception of the CSCO as a high-value business partner.

Leaders of high-performing supply chain organizations invest in key capabilities that drive commercial growth, even for future, hard-to-measure outcomes or when the company is challenged by supply chain risk. Key ways to drive commercial growth in the future supply chain include:

Collaborative, trust-based relationships with key suppliers

Strategy and policies for supply chain risk mitigation

A social learning environment that fosters knowledge exchange among supply chain staff

Dedicated resources to design workforce strategies for future supply chain talent

Customer satisfaction data capture, use and protection within the supply chain organization

Sustainable materials and packaging

Low productivity gains on generative AI (GenAI) investments. Interest in GenAI investments is growing across the C-suite, with GenAI being deployed by a reported 72% of supply chain organizations — but most are experiencing middling results for productivity and ROI.

Economic volatility. Increasing regulation and geopolitical tensions are driving long-term economic uncertainty that CSCOs fear will negatively impact the future supply chain and the business. Tackle the root causes of business uncertainty by increasing geopolitical visibility, leveraging scenario analysis and partnering within the supply chain ecosystem to mitigate disruption.

Simply increasing or decreasing AI investments is not the solution. Rather, future supply chain success will require a redefinition of value. When investing in the future of supply chain, focus not only on operations, but also on the employees who provide data analysis and strategic direction, and the ecosystems that support production. These intangible assets will help fully leverage the productivity of digital supply chain tools.

Having a clear leadership vision can help you navigate these challenges and take the necessary actions to impact future supply chain success.

The future supply chain moves beyond real-time analytics to real-time execution

Ninety-five percent of supply chains must quickly react to change, but only 7% can execute decisions in real time. Without real-time execution, the supply chain will know exactly what to do, but response execution will be delayed. As such, it is expected that digital supply chain investment in real-time decision execution will increase 5x by 2028. With the right technology and skills supporting supply chain analytics, the future supply chain will automate execution and improve performance across the end-to-end value chain. Real-time capabilities require a three-step transformation in supply chain management:

Access to real-time data from across the end-to-end supply chain

The capability to analyze that data on the fly, enabling supply chain organizations to meet enterprise expectations for real-time decision making

Real-time decision making that triggers an expectation for real-time execution

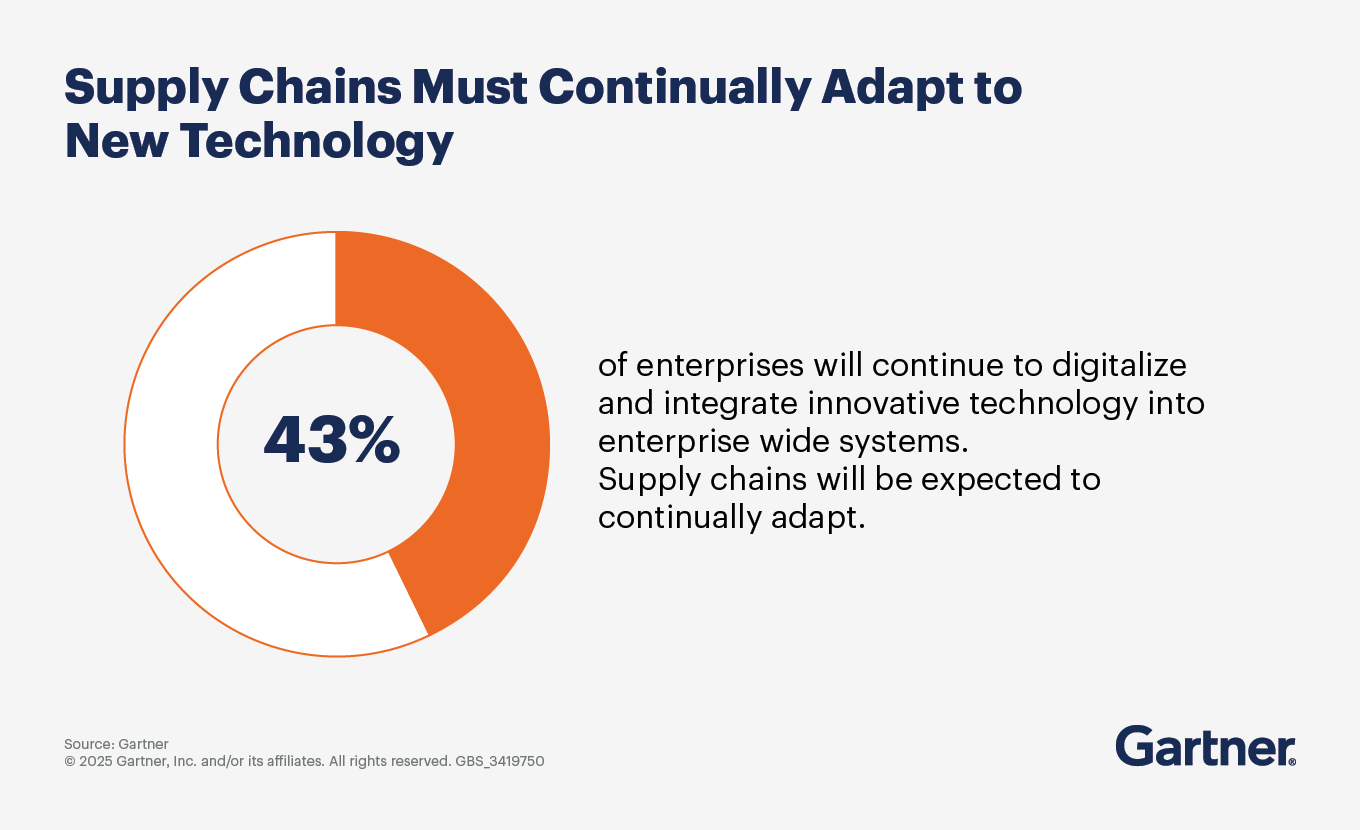

To achieve this, supply chain leaders must overcome the challenges of legacy technology and lack of data, all while utilizing the right technology that enables, not overwhelms. This requires digital supply chain transformation to optimize critical operations with data assets such as artificial intelligence (AI), large language models (LLMs), augmented reality (AR)/virtual reality (VR) and more.

View the future supply chain through a customer experience lens

Supply chains are losing customers amid disruptions. Mounting backorders, low inventory, increased prices and delayed shipments plague supply chains and threaten customer loss. Meanwhile, CEOs increasingly expect supply chains to drive growth, while cutting costs.

Improving customer experience (CX) is a top 3 business priority. Supply chain performance plays a key role in whether a customer is likely to repurchase, and services and offerings should be designed around customer enablement. According to Gartner research, enabled customers are 2x as likely to repurchase, but only 23% of supply chains focus on enabling their customers. Many supply chains lack direct customer insight and focus instead on operational efficiency and on time, in full (OTIF), rather than reducing customer pain points.

To scale customer experiences across the global supply chain, focus supply chain management on these key actions:

Drive future supply chain contribution to growth by gathering voice of the customer (VoC) data to inform customer personas and journey maps that focus on reducing customer and employee effort with targeted solutions.

Streamline the supply chain service menu. The best supply chains offer their capabilities “as a service” and differentiate the customer experience order to order across the buying journey.

Gain funding and address high service delivery costs with cost-to-serve transparency.

Address the challenge that the pace of launching new services is too slow.

Embrace an employee value proposition (EVP) that encourages choice and innovation in work design

Technological advancements and regional disruptions continue to exacerbate talent scarcity and skill set shortage. Over the next three to five years, 63% of supply chain organizations expect the high competition for talent to continue. Only a minority anticipate an increase in available talent from historically less represented regions (such as Africa, the Middle East and Eastern Europe) and from AI deployments.

CSCOs preparing for the future of supply chain aren’t sitting idly by: They are investing in the employee experience and employee value proposition (EVP). But procedural and cultural challenges to work flexibility persist. To attract, retain and engage the talent that future supply chain strategy demands, CSCOs must offer an EVP that moves beyond financial motivation to provide a flexible, purposeful day-to-day employee experience where employees feel understood, autonomous, valued, invested and cared for — and are offered pathways for personal development and choice in work. The competitive advantage here comes from attracting and retaining not only the right skills but having more engaged employees helping your organization succeed.

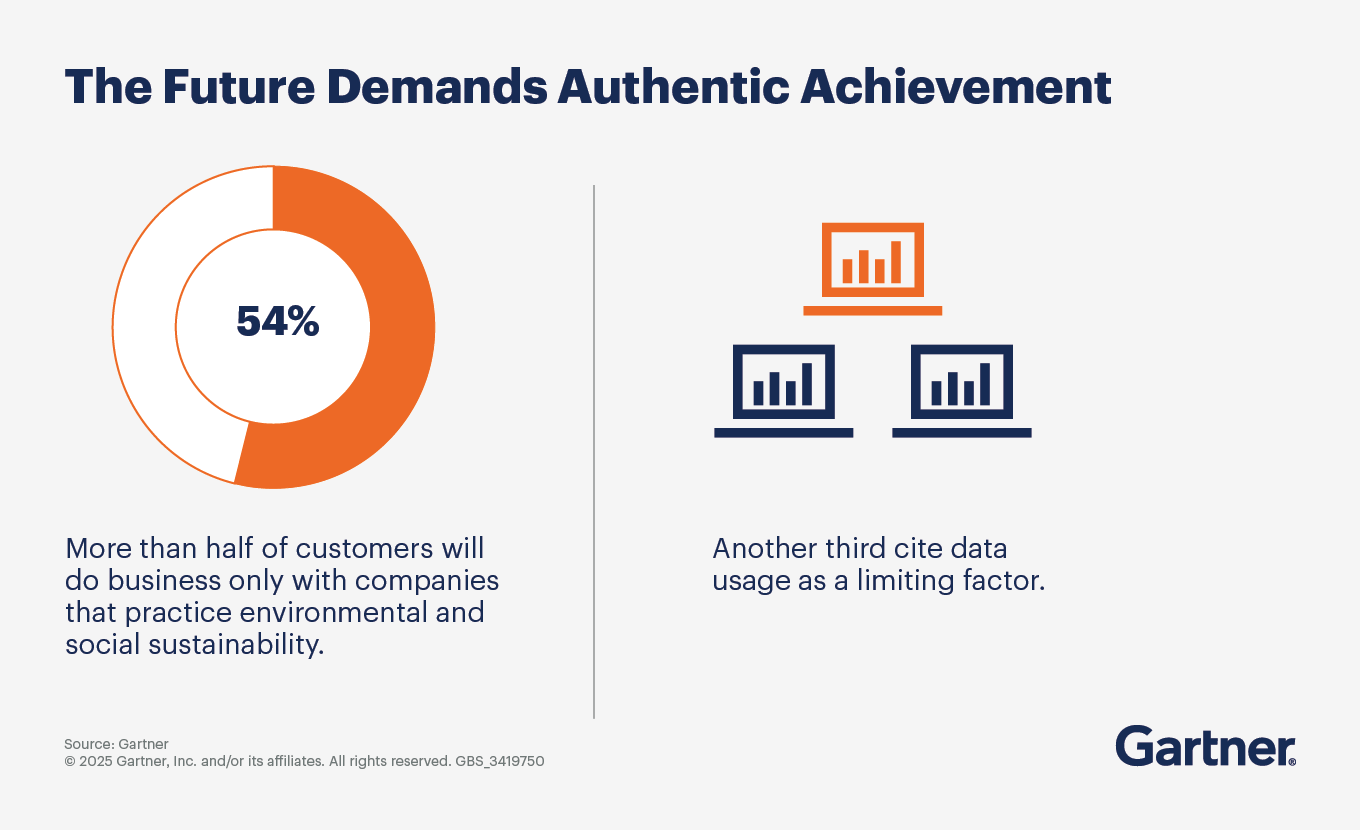

Break through ESG barriers for a sustainable future supply chain

The ambition and scope of sustainability legislation are changing the operating context for supply chains and changing expectations of them. Change is hard and can be overwhelming. A recent Gartner survey finds that 67% of supply chain leaders point to the amount of new ESG regulations as among their top 5 most influential drivers in the next three to five years.

As legislative and stakeholder pressures increase, so does risk. Reinvention to achieve sustainability is critical to future-proof business operations and address global sustainability concerns.Sixty-seven percent of CSCOs are accountable for environmental and social sustainability KPIs. Communication and alignment may improve internal effectiveness and reputation, but supply chain transformation is how you truly realize sustainability and drive change in the end-to-end value chain.

As formerly voluntary activities such as greenhouse gas emissions reporting become legal requirements, leverage these requirements to overcome barriers to progress in three key ways:

Recognize that the supply chain function is a key stakeholder, but not the only stakeholder. Use legislation to enhance cross-functional collaboration with other enterprise leaders.

Anticipate the impact that legislation will have on the supply chain, and incorporate these legislative implications into strategic decision making.

Leverage legislative requirements to overcome barriers to progress in sustainability, build capabilities to drive progress and intentionally capture knock-on benefits from implementation.

Additional resources on the future supply chain

Attend a Conference

Experience Supply Chain conferences

With exclusive insights from Gartner experts on the latest trends, sessions curated for your role and unmatched peer networking, Gartner conferences help you accelerate your priorities.

Gartner Supply Chain Symposium/Xpo™

Orlando, FL

Related future of supply chain resources

Gartner clients: Log in for a complete suite of actionable insights and tools on the future of supply chain.

FAQ on the future supply chain

What will the future supply chain look like?

The future supply chain will use artificial intelligence and other digital technology to automate execution. Not only does this connect decision making across the value chain, it also gives employees more flexibility with work design.

What will the supply chain look like in 2030?

By 2030, sustainability will be embedded in supply chain operations end to end, and sustainability financing will be used to grow revenue (not just as part of isolated cost reduction exercises).

Will the supply chain get better in 2025?

Supply chains can’t afford to let disruptions limit impact. CSCOs must shift focus from operational excellence to commercial innovation — building disruption-tough capabilities that drive competitive advantage.

What is the top supply chain issue for the future?

The top issue for CSCOs is achieving agility and resilience through four supply chain organizational priorities: commercial growth; authentic fulfillment of ESG commitments; real-time execution; and flexible work experiences.

What is the scope of future supply chain management?

The future supply chain will operate three commercial innovation capabilities to support growth: supply chain capabilities “as a service,” a consolidated service menu; and operating model modularity and flexibility.

Drive stronger performance on your mission-critical priorities.