Addressing supply chain risks: Comprehensive strategy and guide to prevent and mitigate business disruptions

- Gartner client? Log in for personalized search results.

Top Supply Chain Risks and Mitigation Strategies

Avoiding geopolitical risk limits your growth potential. Learn how to embrace it.

CSCOs say these geopolitical risks have hurt supply chain performance the most: Russia-NATO tension; U.S.-China competition; and COVID-19 fallout.

Download this supply chain risk report to learn how to drive growth from supply chain risk management (SCRM), even amid urgent challenges like deglobalization, cyberattacks and energy scarcity.

- Clarify your supply chain’s operating boundaries.

- Do scenario planning for future supply chain risks.

- Preview disruptions to global trade, resourcing and operations.

Increase supply chain risk readiness to combat market disruption

Enhance your risk management maturity by continuously reviewing governance processes and introducing technology solutions to optimize business performance and achieve stakeholder expectations.

Risk Mitigation

SCRM Technology

SCRM Best Practices

Identify and assess supply chain risks to improve your response strategies

Supply chain teams must constantly address risk, whether generated internally (e.g., workforce dynamics, business model shifts) or externally (e.g., macroeconomic disruption, environment and climate dynamics). Supply chain disruptions can put business performance at risk, cause reputational and financial damage, and threaten organizational viability.

To effectively mitigate supply chain risk, it is vital that chief supply chain officers (CSCOs) are aware of, and comfortable with, the level of risk exposure and the effectiveness of the controls in place for the risks that may impact the business. Without this knowledge, supply chain risk mitigation strategies will not be appropriately resourced and the risk of control failures increases.

Gartner analysts recommend following these steps to enhance supply chain resilience against potential disruptions:

Start by identifying risks. To obtain a consistent, holistic view of supply chain risks, be sure to examine not only the risks inside the supply chain function, but also external risks driven from customers, suppliers, regulators and NGOs. Additionally, organizational risk experts (e.g., corporate enterprise risk teams, internal audit) can provide risk appetite and risk reporting insights.

Next, assess the materiality of risks and document the controls that can minimize the likelihood of a risk occurring or help to respond to a risk after an event. Effective strategies for mitigating supply chain risks in your business include due diligence, supplier audits, vulnerability analysis and continuity plans.

Finally, evaluate your risk appetite, documenting the most significant risks that will require enhanced controls. Examples include a single-sourced supplier based in a politically unstable location and key IT systems vulnerable to cyberattacks. When faced with these risks, CSCOs will require additional resources from corporate management and potentially the board to manage the impact to the supply chain organization.

Utilize technology in SCRM to increase effectiveness of supplier risk tactics

Key tenets of supply chain risk management are enhancing resilience and improving competitiveness.

Supply chain transformation, however, complicates supply chain risk management. Lean but complex and globally dispersed operations add risk, making it difficult to achieve agility and competitive advantage from the supply chain risk management strategy.

Companies leveraging supply chain technologies and digital transformation in risk management increase their effectiveness in supplier risk tactics by nearly 2x. Risk professionals and their peers in the supply chain and procurement organizations must first develop a supply chain strategy that identifies potential supply chain failure points and creates control measures to prevent interruption. Enterprise risk management (ERM) software, advanced analytics and digital technologies support the supply chain risk management strategy by enabling continuous risk review. Data transparency equips supply chain/procurement leaders responsible for supply chain risk management with the best information to determine risk-reward trade-offs. Additionally, many companies have automated risk assessment and monitoring.

Supply chain professionals seeking how to implement a robust supply chain risk governance framework can turn to new digital solutions like supply chain/procurement monitoring, supplier financial risk assessment (most effective for public companies) and geopolitical risk capture. A cautious and purpose-driven evaluation of these solutions is recommended since few, if any, have predictive analytics capabilities built into them, although vendors claim they are developing machine learning (ML) and artificial intelligence (AI) to spot potential issues.

Supply chain risk appetite statements transform SCRM into a value-add

Eighty-nine percent of companies experienced a supplier risk event in the past five years, and almost two-thirds were delayed in responding because they lacked a framework to continuously predict, assess and manage sourcing risks. Despite this, only 35% of companies have a formal enterprisewide risk appetite statement in place, and even fewer (11%) have reached the maturity level of business-unit-customized risk appetite statements.

No company has complete mitigation readiness with scenario-based action plans for disruptions in the supply chain. At the same time, no company is immune to supplier risk, with most events attributed to supplier financials, capacity or compliance issues. It is critical to improve your risk readiness through synchronized business and supply chain/procurement strategies.

The risk appetite definition is the risk exposure assumed to achieve strategic and operational goals, sustain competitiveness and increase agility. Establishing a supply chain risk appetite statement drives risk awareness in the value chain and enables supply chain/procurement leaders to predict risk more accurately and put corrective measures in action faster. Formalizing risk appetite helps turn supply chain risk management into a value creation lever.

Key benefits of formalizing risk appetite:

Aligns business imperatives and supply chain/procurement goals. Connects business and supply chain/procurement strategies.

Elevates supply chain risk management to become more comprehensive and relevant.

Promotes continuous discussion at the executive level on supply chain risk management as a driver to thrive in uncertainty.

Improves the long-term prospects of the company.

It is increasingly important in a faster-paced global economy with greater complexities and more interdependencies across value chains to have a well-defined supply chain risk appetite statement. Without one, supply chain risk management may over-focus on post-risk-event impact containment, correction and recovery. Many stakeholders point directly to supply chain/procurement for ownership and call for action.

Supply chain risk management best practices are preparing, drafting and operationalizing a risk appetite statement. Gartner recommends following these four steps:

Secure risk appetite buy-in. Ensure internal stakeholders as well as external partners and suppliers are aligned on a common set of risk management goals.

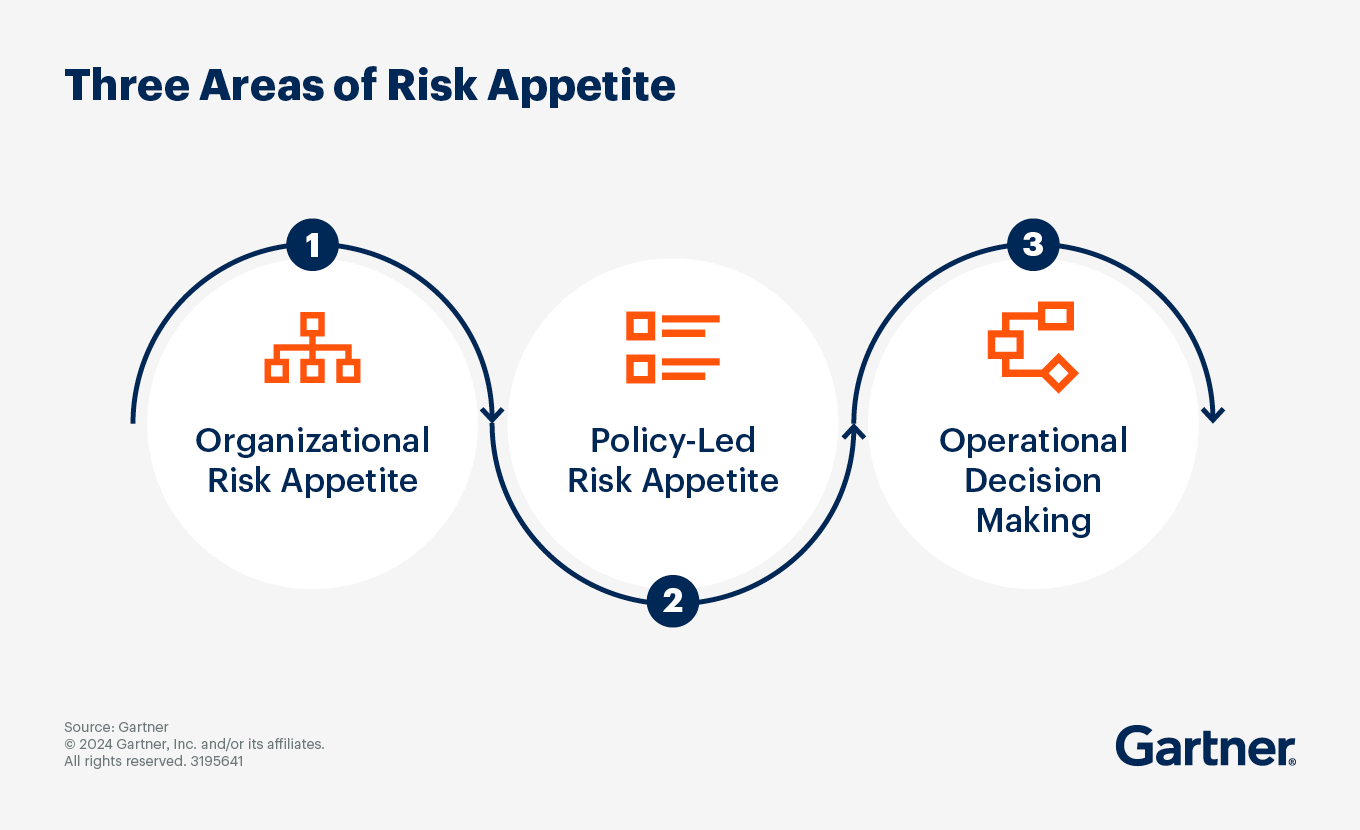

Assess risk preferences. Understand the organizational risk appetite (determined by the board) and the policy-led risk appetite (led by senior organizational leaders and subject matter experts), as well as the operational decision making of supply chain and business unit leaders.

Draft the risk appetite statement. Failure to provide guidance on how to act in uncertain situations often results in supply chain strategy decisions that fall outside the range of acceptable risk.

Communicate the supply chain risk appetite. Identify the critical risk appetite information to communicate to stakeholders, reinforce how and when to apply risk appetite guidance, and conduct continuous review to ensure maximum value creation.

Attend a Conference

Experience Supply Chain conferences

With exclusive insights from Gartner experts on the latest trends, sessions curated for your role and unmatched peer networking, Gartner conferences help you accelerate your priorities.

Gartner Supply Chain Symposium/Xpo™

Orlando, FL

Portfolio of supply chain risk management tools

Gartner clients: Log in for additional actionable insights on supply chain risk management.

FAQ on supply chain risk management

What is supply chain risk?

Supply chain risk threatens the operation and effectiveness of supply chain processes. Supply chain risks can be categorized as economical, environmental, political, regulatory/legal, social/cultural, technological and trust/ethics based. Examples include inflation, aging public infrastructure, climate change, natural disasters, new trade agreements, unilateral sanctions, carbon tax, new pandemics, profound social instability, AI, cyber crime, human error/accidents and viral misinformation.

Why is supply chain risk management important?

Risk management enables supply chain organizations to thrive despite uncertainty, disruption and complexity in the business environment. Risk assessment techniques for supply chain continuity planning include scenario and predictive analysis. Being able to sense and respond to unanticipated changes in demand or supply — quickly and reliably and without sacrificing cost or quality — is a hallmark of successful supply chain continuity planning.

How can we assess supply chain risks?

Most organizations focus on assessing internal risks and neglect the possible impact of external environment changes. Risk assessment strategies must follow a consistent methodology. Begin by examining risk and impact, and then determine the requirements to resolve the risk and the expected result. Assess internal drivers of risk like cost, growth and complexity; and external drivers of risk including disruptive innovation, competition and regulatory change.

What strategies can we use to mitigate supply chain risks?

Supply chain professionals struggle with how to manage supply chain risks and prevent business disruptions. Supply chain risk mitigation is about identifying and managing external and third-party risks, and building supply chain disruption recovery capabilities. Business disruption prevention begins with defining risk thresholds for supply chain/procurement activities. Then develop risk governance in supply chains — e.g., risk oversight, risk-based decision making.

What is technology’s role in supply chain risk management?

Technology has proven to be a driver of supply chain risk management for those supply chain professionals seeking best practices for assessing and addressing supply chain risks. Utilizing technology in SCRM strategy increases the effectiveness of supplier risk evaluation by almost 2x. With risks evolving and new, high-impact risks emerging with increased complexity and velocity, Gartner analysts recommend automating risk assessment and monitoring.

Drive stronger performance on your mission-critical priorities.