Transform the purpose of supply chain logistics to drive greater business impact.

- Gartner client? Log in for personalized search results.

Supply Chain Logistics Management: Guide, Insights and Strategy

Rethink your strategy to increase the odds of logistics transformation success

Since 2020, 80% of companies have undertaken logistics transformation almost yearly. A staggering 76% of these logistics transformations have failed.

Download the supply chain logistics management guide to learn a new, innovative strategy that improves the success rate of logistics transformations by 62%.

- Smart investment in supply chain logistics management

- Competitive advantage from the logistics organization

- Employee engagement in the logistics transformation

Drive competitive advantage from supply chain logistics

For supply chain logistics management to enable business and customer outcomes, you need the right technology and talent in place.

Logistics Costs

Logistics Strategy

Logistics Ops

Logistics Tech

Talent Pipeline

Cost reduction alone won’t temper capacity constraints and price spikes

Inflationary pressure, the high cost of fuel, and escalating wages drive persistently high logistics spend. With logistics costs accounting for a significant portion of the overall supply chain management expenditure (nearly 80% at some companies, according to Gartner research), it’s not surprising that global chief supply chain officers (GCSCOs) are seeking successful strategies for reducing supply chain logistics costs. But external cost optimization opportunities are hard to find in a business environment characterized by transport capacity constraints and stubbornly high rates. Faced with budgetary increases year over year, a looming recession and increasing expectations from supply chain leaders, logistics managers must get smarter at supply chain cost optimization.

This starts with differentiating cost reduction and cost optimization opportunities. GCSCOs seeking how to optimize supply chain logistics for efficiency usually start by eliminating spend and saving money. Examples of logistics cost reduction activities include: negotiating lower transport rates and better third-party logistics contracts; deferring technology upgrades/automation; and identifying cost leakage such as incorrect invoicing, excessive waiting times and demurrage.

On the other hand, cost optimization activities, such as eliminating wasteful and redundant processes and creating self-service tools, are designed to drive efficiency, productivity and innovation from logistics management.

Mature logistics organizations combine both cost reduction and cost optimization initiatives to achieve the best outcomes. Segment and prioritize cost optimization opportunities using varying time horizons, such as short-, medium- and long-term, and expected deliverables (e.g., rework upstream order policies; establish a control tower operation; produce cost-to-serve analysis). Bear in mind that cost optimization initiatives may require an initial increase in expenditure through added investment.

Depending on whether the logistics function is seeking to reduce costs by operating better or deliver more sustainable cost optimization by altogether transforming how it does things, logistics managers must manage stakeholder expectations. Demonstrate trade-offs between cost control and service excellence using metrics such as days to deliver; on-time, in full; and cost to serve. Note that some compromise around service and performance may be necessary to achieve cost optimization in supply chain logistics management.

Cost optimization in supply chain logistics management must seek to balance service delivery with the best customer experience, at the right level of cost to be effective. It must also engage elements of cost reduction to respond to the immediate needs of the business when that business is facing economic challenges.

Logistics is the new differentiator for improving customer experience

Operational efficiency and managing costs have always been the primary aims of logistics strategy. But the rise in e-commerce and the corresponding rise in customer expectations have transformed supply chain strategy, and now the importance of logistics strategy to enabling a differentiated customer experience is huge — especially through sustainable logistics practices.

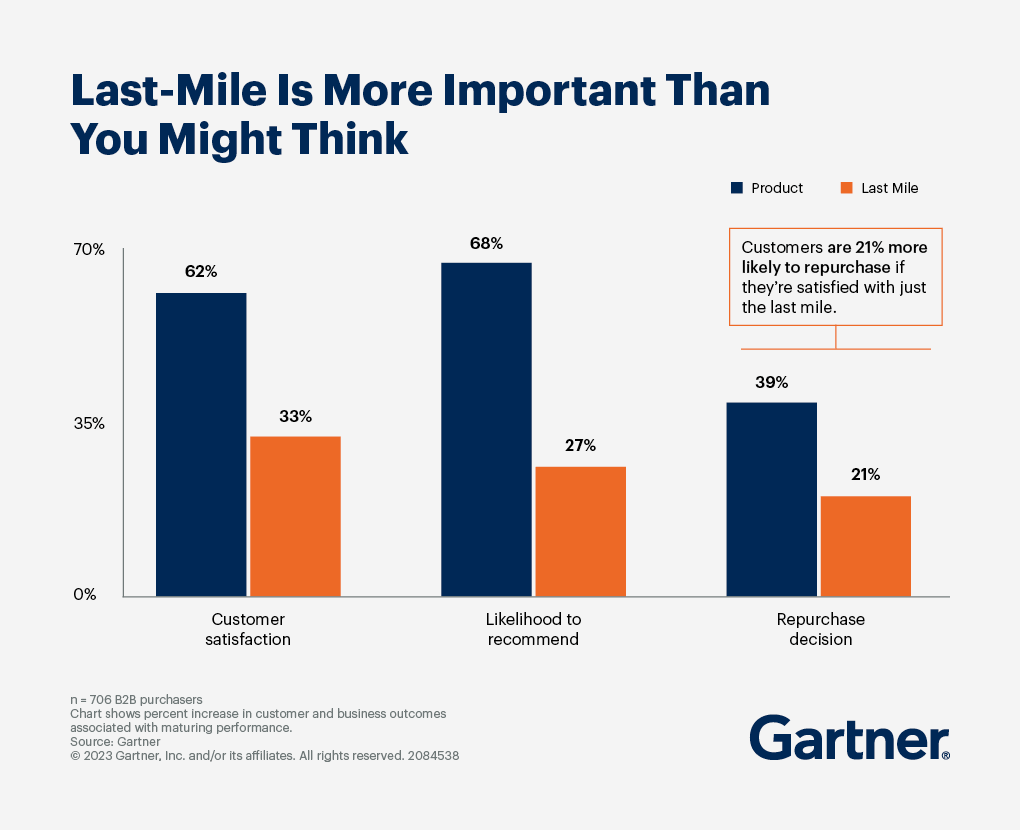

Gartner research shows that, although product continues to dominate when it comes to recommending and repurchasing decisions, logistics also has a sizable impact on these decision metrics. In fact, customers are 21% more likely to repurchase if they’re satisfied with just the last-mile logistics. Logistics-driven service differentiation can be a valuable addition to the already-existing focus on product.

In response, logistics leaders are prioritizing improvements to technology systems and data quality in order to drive greater visibility, tracking, route planning and a more sophisticated interface with customers.

To enable greater customer focus in supply chain management, logistics leaders need to secure the following:

Leadership buy-in. Logistics leaders find that their function is often viewed with a narrow lens. Changing leadership’s view on what logistics can offer and securing buy-in from leaders in pivoting to a customer-first focus are critical.

Better customer understanding. Logistics leaders have not invested sufficient time and resources in understanding who their customer is and what they want. Go beyond measuring customer satisfaction to assessing a broad range of service criteria, such as speed, reliability, transparency, customization, ease of returns, sustainability, packaging and cost.

Cross-functional partnerships. Instead of fighting for customer time and attention with colleagues in the sales, marketing and customer relations functions, combine perspectives to improve the overall customer experience. For example, align with upstream demand planning to identify better pickups and route optimization.

Improving logistics processes and metrics for greater efficiency is a key priority

Today’s operations manager struggles to manage a complicated product portfolio, challenging routes to market, rapidly changing customer requirements and growing network complexity. When optimizing logistics operations for cost-efficiency, start by measuring the effectiveness of critical logistics capabilities and their impact on supply chain management and the overall logistics network. Without a well-defined and aligned supply chain analytics strategy, customer service failures will inevitably arise from supply chain logistics management.

Next, streamline supply chain logistics operations by deploying a comprehensive and actionable logistics performance dashboard. This starts with appointing an executive champion who will define logistics metrics, targets and thresholds. Few companies are lacking in metrics. On the contrary, there are so many of them that it causes confusion around which metrics will drive improvement on corporate objectives and which ones are being reported just for the sake of reporting. Limit the dashboard to those logistics management metrics that will help you evaluate structural costs (both fixed and variable costs related to design choices) and operating inefficiencies (e.g., operational waste, cost of nonconformance, opportunity losses) that may result in supply chain risk.

Then collect logistics management metrics at the operational or functional level and organize them by warehouse type, location or region, supply chain type (e.g., finished goods versus raw material; store retail versus e-commerce; B2B versus B2C) or other segmentation criteria. Regardless of the segmentation, core supply chain management metrics should always be the same across all sites to achieve continuity and clarity.

Emerging logistics technology facilitates and improves supply chain ecosystems

Global economic conditions challenge companies to find new ways to drive supply chain process improvements, cost savings, higher efficiencies and better business outcomes.

Meanwhile, logistics organizations have long focused on execution excellence and have trailed other parts of supply chain management in adopting more robust decision support capabilities. Logistics organizations must improve their responsiveness and flexibility while addressing core business and financial realities.

Many invest in end-to-end supply chain solutions as part of digital supply chain and technology transformation to drive automated supply chain processes and promote efficient logistics management. Logistics technology solutions and automated logistics systems are accelerating in areas like warehouse resource planning, inventory optimization, freight forwarding, transportation forecasting and global trade governance.

According to Gartner research, by 2027:

More than three-quarters of last-mile deliveries to end customers in North America and Europe will have real-time supply chain tracking with visibility into delivery windows and ETAs.

Eighty percent of global supply chains will have adopted logistics control towers as the operating model of choice to improve shipment visibility and performance analytics.

More than 60% of large organizations will have implemented fourth-party logistics providers (4PLs) as their preferred outsourcing model to accelerate their supply chain transformation.

Logistics management solutions are useful in managing supply chain disruption, rampant inflation, rising energy costs, growing labor shortages and increasing risk due to geopolitical tensions and cybersecurity threats.

Logistics must improve its image to attract and retain next-generation talent

Almost every industry is experiencing a talent shortage, and in logistics, that talent shortage is even more acute. The pandemic accelerated retirement for many baby boomers in operations management positions, and with the current demand, there aren’t enough young people to backfill the pipeline. What’s more, logistics is plagued by limited, linear and obsolete career paths, and few companies have identified motivational factors beyond salary increments for attracting and retaining logistics employees.

To build a high-performing logistics workforce, Gartner recommends adopting these supply chain organization design and talent best practices:

Highlight cutting-edge logistics technology. The logistics field is becoming more technology-based through big data, the Internet of Things (IoT), artificial intelligence (AI) and virtual reality, meaning tech-savvy young people will be at the forefront of operating and leading more efficient businesses. To demonstrate the value of a career in logistics to Gen Z and millennial talent, promote the digitalization of various logistics tasks and the use of smartphones and tablets in day-to-day supply chain management workflows.

Offer choices around work location and hours. Gen Z and millennial employees value a flexible work-life balance above all else. But how do you offer workplace flexibility for hands-on warehousing and other logistics frontline positions? One good option is to allow employees to schedule and trade their own shifts. With each decision that employees have flexibility over — such as location, schedule and how much they work — the percentage of high-performing employees increases.

- Invest in skills development. Having the opportunity to grow is important to Gen Z and millennial employees. Emphasize continual professional development and modify the logistics culture to cultivate mobility, exploration and ambition.

Evolve the logistics career path. Traditional career ladders are outdated in a digitalized world where logistics opportunities are plentiful. Modernize your logistics career path to attract top talent, retain existing staff and develop a more cross-functional supply chain organization.

Promote the company’s commitment to sustainability. According to Gartner research, 47% of supply chain leaders say that Gen Z and millennial values are driving them to place greater emphasis on supply chain sustainability. While there are other factors pushing logistics leaders toward reducing their carbon footprint or adding sustainability-related KPIs, this increased focus toward sustainability will attract younger generations to work in logistics organizations.

Supply chain logistics management case studies

Attend a Conference

Experience Supply Chain conferences

With exclusive insights from Gartner experts on the latest trends, sessions curated for your role and unmatched peer networking, Gartner conferences help you accelerate your priorities.

Gartner Supply Chain Symposium/Xpo™

Orlando, FL

Related supply chain logistics resources

Gartner clients: Log in for a complete suite of actionable insights and tools on supply chain logistics.

Supply chain logistics management FAQ

What is supply chain logistics management?

Supply chain logistics management is the alignment of processes related to the physical flow of materials and products from source to final destination. The objectives of logistics management are: global supply chain logistics (import/export); logistics transportation; inbound logistics and outbound logistics; shipping and receiving; warehousing; inventory management; product purchasing; production planning; and customer service.

How do I implement supply chain logistics management?

Today’s customer-centric economy demands best practices for supply chain logistics management. The top strategies for improving logistics management are: aligning the full suite of logistics capabilities to business objectives; avoiding isolated investment in individual aspects of logistics performance (service structure, efficiency and cost); and establishing a common framework for logistics development.

What’s new in supply chain logistics management?

Instability in global trade, demand for localized and personalized logistics, a persistent shortage of logistics talent, and constrained budgets are key trends challenging logistics teams today. The future of logistics and supply chain management involves moving beyond customer satisfaction to enabling customers to get their own jobs done — e.g., ship direct from manufacturer to save the customer time and money; test devices and preload software in the warehouse to improve the customer experience.

How do I master supply chain logistics management in 2025?

Future challenges of logistics management involve balancing the need for execution with supply chain optimization. Integrating logistics management capabilities to drive efficiency and productivity — while increasing focus on sustainability targets, talent and customer expectations — will separate leaders from the pack. Deploy traditional functional expertise while developing new skills and competencies to deliver consistent, cost-effective and reliable supply chain logistics solutions.

Can technology improve supply chain logistics management?

Labor shortages and rising labor costs are the primary drivers for technology investment. Another critical driver is digitizing the supply chain processes and capabilities that connect supply chain management professionals and enable logistics management. Logistics network planning refers to the technology solutions for supply chain logistics operations that analyze the trade-offs among inventory quantities, number and location of warehouses, and transportation costs.

Drive stronger performance on your mission-critical priorities.