By Stan Aronow | February 21, 2025

Tariff Analysis to Action

August 29 2025

By Stan Aronow | February 21, 2025

Recently, I joined a roundtable discussion with a group of supply chain executives from larger, more advanced companies on the topic of strategies for navigating the current landscape of tariff and trade uncertainties. The discussion emphasized supply chain’s critical role as a "safe harbor" for companies facing market volatility. I was pleasantly surprised by the discussion’s vibe; it felt more poised and less reactionary than I expected.

The conversation highlighted that we’re operating in an environment that’s more than an aggregation of individual disruptions. Instead, it’s a world of extremes where a decision’s potential outcomes can vary significantly.

That said, most of the supply chain organizations in the room felt that their previously-built ability to run detailed scenario plans, coupled with their operations’ resilience and adaptability to pivot sources and locations, would allow them to respond accordingly, no matter how trade policies land. While costs may increase and need to be absorbed or passed along in some cases, these supply chains feel that the model and machine is in place to respond to a broader set of outcomes.

The discussion also highlighted the need to shift from a narrative focused on risk and disruption to one of empowerment and opportunity. While the challenges are significant, there was a sense that boards and executive committees are looking to supply chains for leadership and help navigating the issues related to tariffs.

This perspective is consistent with a recent Gartner report published by Suzie Petrusic, Thomas O’Connor et al. titled “Use Tariff Volatility to Drive Competitive Advantage” (subscription required). This research details actions for executive leaders to turn tariff volatility into a competitive advantage.

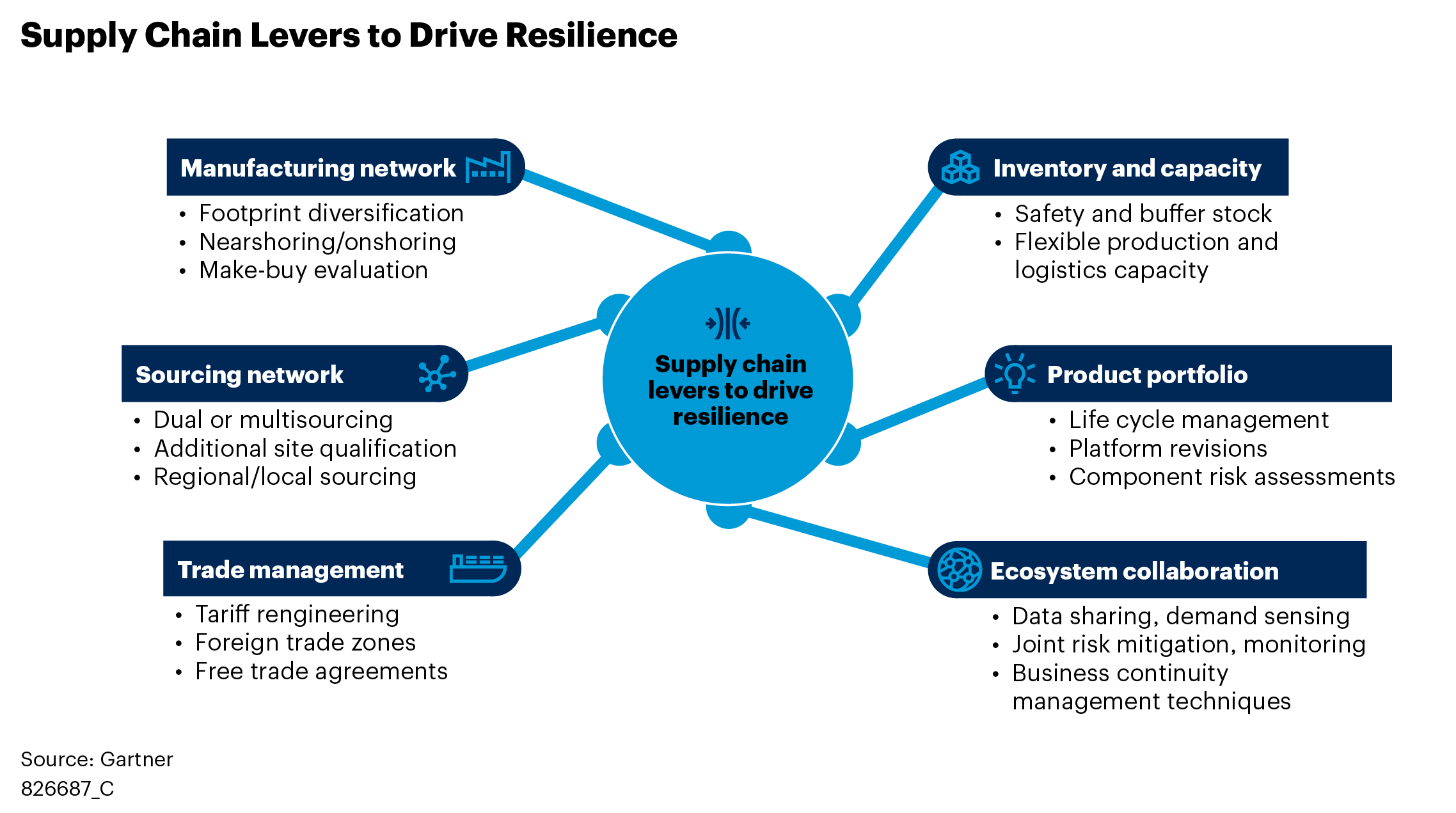

As shown in the figure below, Petrusic, O’Connor and team suggest exploring a wide range of mitigation levers, including changing the supply base, investing in new suppliers and locations, engaging with new external manufacturers, redesigning products or collaborating more intentionally across your ecosystem. These are the options one would expect supply chain leadership to discuss, so they recommend also asking about options you’re not hearing.

Leaders in my recent roundtable highlighted similar actions to those shown above. Some of them also noted that previous moves to create more circular supply chains for raw materials created some buffer against potential future tariffs.

There was also a lot of emphasis on supply chain agility, specifically, supply chain visibility tools. When combined with AI-based analytics, these tools allow supply chains to quickly pivot between sources and locations of supply in response to new trade policies that can quickly increase import costs.

In the domain of product design, one innovative idea was to create "tariff engineers" who monitor the trade environment to understand potential impacts on the cost of goods sold, then proactively identify strategies to mitigate those impacts through dematerialization and alternative materials or suppliers.

The need for proactive planning and scenario analysis was another recurring theme, including the ability to bring supply chain capacity considerations early into the business planning and financial modeling processes.

The group emphasized the importance of leveraging existing tools and capabilities within the supply chain, just with greater agility. Many of them developed new muscles during the pandemic and post-pandemic inflationary periods that they are reusing in the current environment.

For supply chains that are earlier in their capability development journeys, the message was that it is never too late to start (in the context of preparing for future challenges). Ultimately, embracing these strategies will enable your supply chain to drive sustainable, profitable growth for your organization.

Overall, it was an encouraging conversation. As one leader noted, the power of our community lies in the ability to come together to discuss these challenges and to learn from each other’s experiences to strengthen our collective capabilities.

Stan Aronow

VP Distinguished Advisor

Gartner Supply Chain

Stan.Aronow@gartner.com

Learn more about Navigating Tariffs for CSCOs

Beyond Supply Chain

Subscribe on LinkedIn to receive the biweekly Beyond Supply Chain newsletter.

![[ALT TEXT]](https://emt.gartnerweb.com/ngw/globalassets/en/supply-chain/blog/beyond-supply-chain/images/beyond-supply-chaain-21-february.jpg)