Automation and robotics adoption is accelerating. Choosing the best-fit software will keep you from falling behind.

- Gartner client? Log in for personalized search results.

Build a Competitive Supply Chain Automation Strategy That Avoids Costly Mistakes

By Simon Tunstall | October 7, 2025

Having the right automation software for your warehouse environment is critical — and elusive

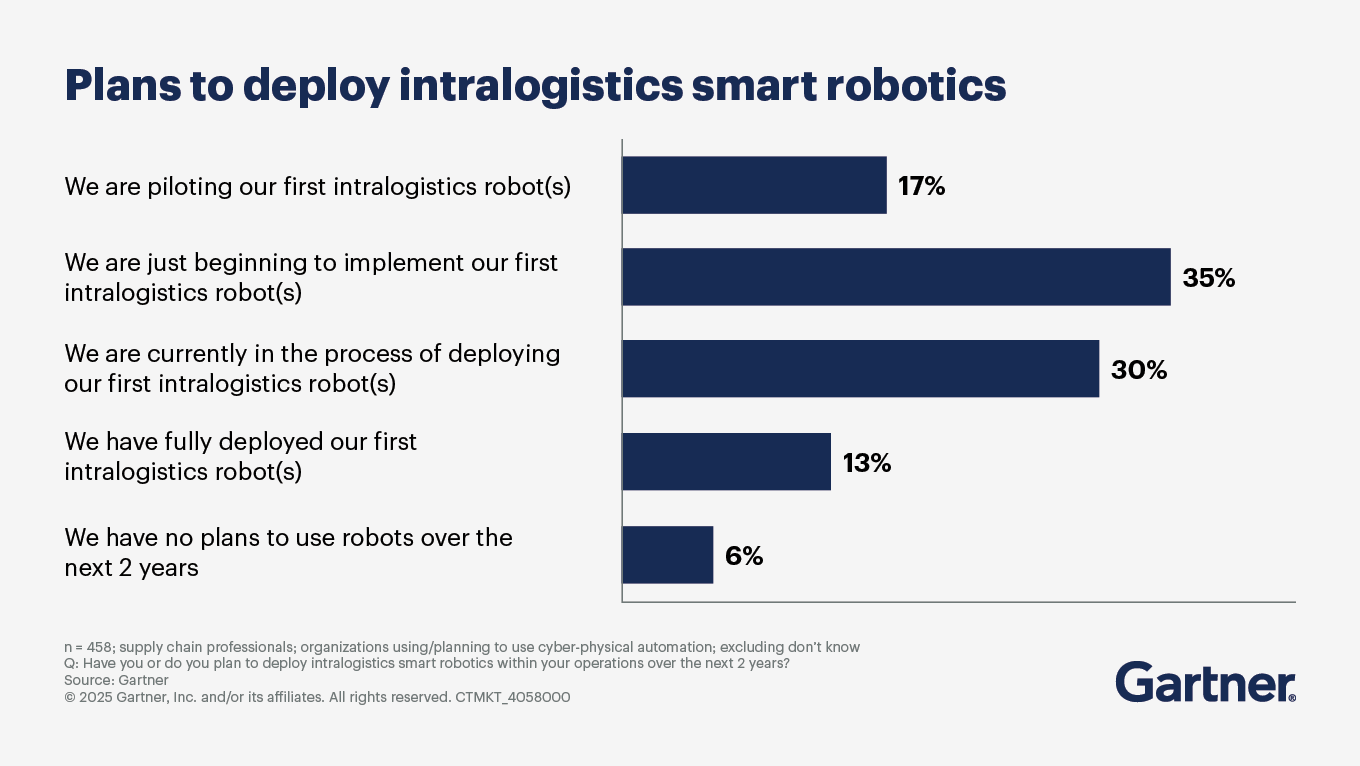

By 2028, 80% of warehouses and distribution centers will deploy some form of warehouse automation equipment. This growing adoption of materials handling equipment (MHE) and intralogistics smart robotics (ISR) brings huge opportunities — but narrowing down the available software options to manage it is often a massive challenge.

The right logistics and fulfillment technology can set an organization apart. The wrong technology can lead to failed automation, cost and schedule overruns, unnecessary reimplementations, project delays and even lost revenue. To maximize returns on automation investments and ensure your organization remains competitive, connecting automation strategy to changing business needs is a must.

Maximize success with an aligned technology strategy

Understanding how warehouse automation software fits into your specific environment is essential to choosing the best options. Start by following these steps.

Assess the complexity of your warehouse or distribution center

Warehouse complexity is the key driver of warehouse management scale and scope. Although size may seem the most obvious indicator, other factors — such as constraints, layout and location, volume of work, cycle time throughput, adaptability, types of work, MHE automation, variability and product characteristics — also shape warehouse complexity.

Determine complexity at the facility level. Then develop an automation strategy that considers the needs of each warehouse in your network and where automation could improve operations.

Weigh automation software types by their functions

Understanding the various software types is the first step to finding the best fit for your warehouse environment. The main types include the following:

Programmable logic controllers (PLC) activate and manage individual devices (like conveyor controls and carousels) to ensure commands are executed.

Material flow control (MFC) optimizes load handler routing, sequencing and transportation.

Robot control systems (RCS) or robot fleet management systems (FMS) route ISRs in the warehouse operation to prevent “traffic jams.”

Warehouse control systems (WCS) manage storage and retrieval by translating business transactional information into real-time automation instructions.

Warehouse execution systems (WES) build on a WCS’s near-real-time insight, but add business process logic to this layer.

Warehouse management systems (WMS) handle business transactions like inventory management and receiving, picking, packing and shipping orders. Enhanced WMS focuses on process integrity and productivity improvement.

Enterprise resource planning (ERP), an integrated suite of business applications, may include some warehouse management capabilities.

Multiagent orchestration (MAO) platforms integrate and assign work between business applications, robot fleets and other automated and physical agents.

Unified (or universal) control systems (UCS) are emerging applications that aim to unify control between conventional MHE systems, ISRs and other technologies.

Define your environment to guide warehouse automation software selection

Warehouse automation — and its associated software — can range from minimal to extensive. For example:

Simple warehouses with no WMS might use ERP directly connected to basic automation (PLCs/MHE vendor’s systems).

In low-automation warehouses, WMS can connect to PLCs/robots, sometimes using VDA 5050–compliant robots for basic transport without an MAO platform.

In moderate-complexity, high-automation warehouses with one MHE vendor, the WMS might integrate directly with the vendor’s MFC/WCS.

For complex, moderately/highly automated sites with one main MHE vendor, the WMS might integrate with the vendor’s WCS, ideal for new (“greenfield”) sites.

Complex sites with extensive automation from multiple vendors can use WMS with embedded/separate WCS for flexibility.

Warehouses with mixed automation maturity and brands might use independent WCS for optimized integration, but clarify accountability.

Highly complex or blended manual/automated environments could use WES (or enhanced WCS) for advanced orchestration and optimization.

In multirobot, multivendor environments, MAO platforms simplify the integration and orchestration of diverse robotics.

Supply chain automation FAQs

What are the challenges of choosing the right warehouse automation equipment and software?

The distribution environment is constantly changing. Without carefully evaluating automation options against both current and planned warehouse environments, supply chain technology leaders have often spent large sums on equipment and software that don’t flex to changing demands. This can lead to millions of dollars in wasted capital expenditure — sometimes even lost revenue.

What is an ideal approach to choosing supply chain automation technology?

Ideally, software solutions should support both highly automated and hybrid manual and automated environments. Remaining flexible in managing change — such as demographics and labor, customer demands, and emerging technologies across the warehouse environment — is also important.

Recommended resources for Gartner clients*:

Use the Right Software to Support Warehouse Automation and Robotics

Innovation Insight: Multiagent Orchestration Platforms

Tool: Stratify Your Warehouse Operations to Determine the Right-Fit WMS and Improvement Strategy

*Note that some documents may not be available to all Gartner clients.

Attend a Conference

Experience Supply Chain conferences

With exclusive insights from Gartner experts on the latest trends, sessions curated for your role and unmatched peer networking, Gartner conferences help you accelerate your priorities.

Gartner Supply Chain Symposium/Xpo™

Orlando, FL

Drive stronger performance on your mission-critical priorities.